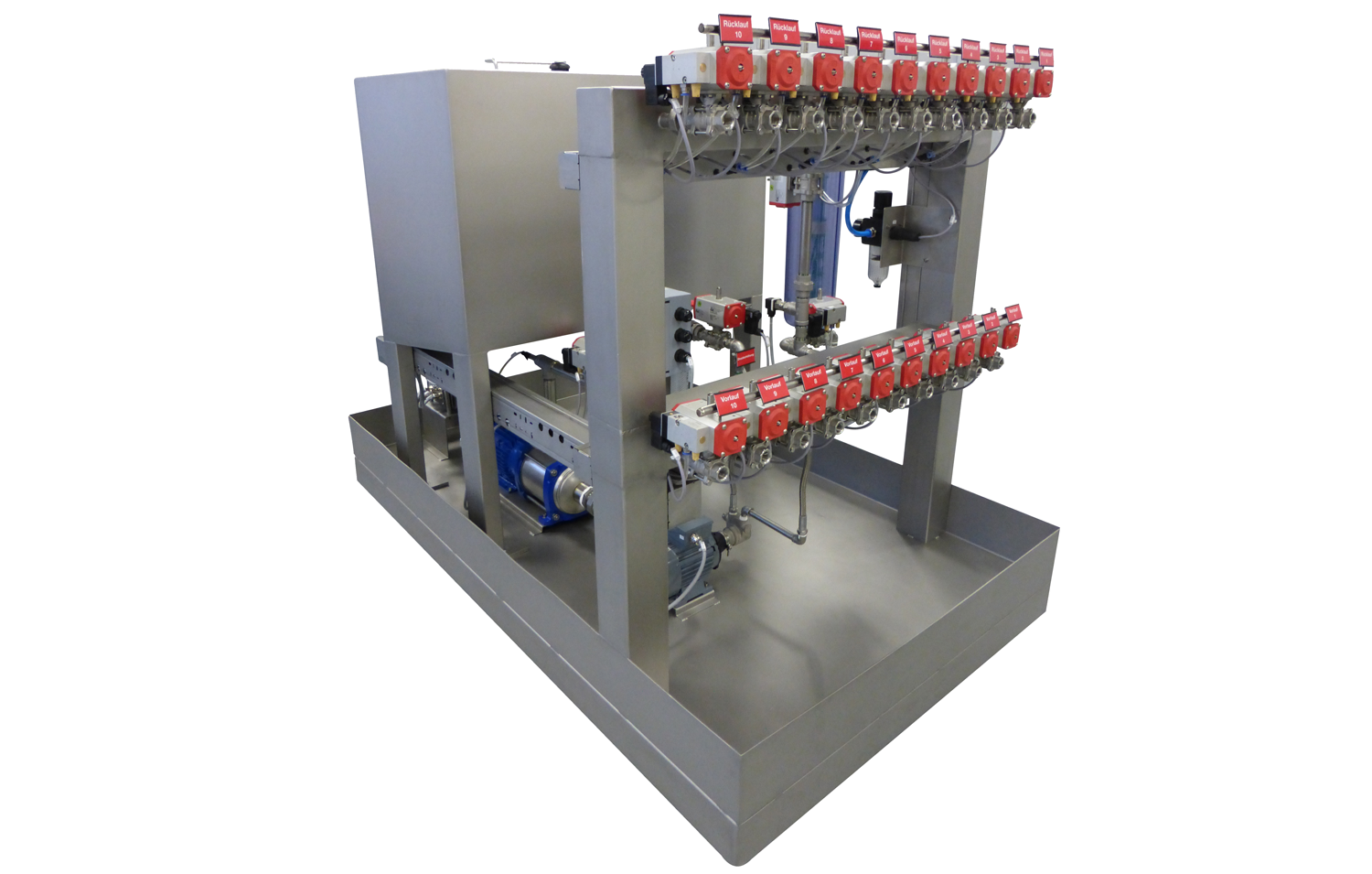

Rinsing system for temperature control channels has been expanded

by MACO Vision GmbH

The SPM300 system has been specifically developed for the cleaning and testing of large and complex die-casting and injection-molding tools and has now been upgraded to support up to 12 circuits. This makes the system ideally suited for tools with a high number of cooling channels and complex geometries.

Thanks to the integrated PLC control, customized flushing programs can be created, stored, and executed repeatedly, ensuring efficient and process-reliable cooling channel cleaning.

At the end of each cleaning cycle, the relevant flow rate and pressure test values are displayed for each individual circuit. If required, these data can be saved to a USB device for documentation and quality assurance purposes.

By enabling the parallel cleaning and testing of multiple circuits, the SPM300 significantly reduces the time and effort required to service tools with a large number of cooling circuits, while simultaneously increasing process reliability and transparency.